|

Hay Royds Colliery

Originally submitted by Alex Potts & later amended

by Dave Douglass

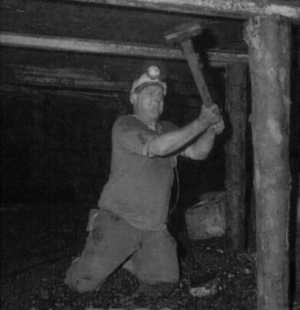

Photographs by P R Deakin - Supplied by Gareth Rimmington

|

|

Hay Royds Colliery

Just three West Yorkshire Collieries have survived into this

new millenium, HayRoyds is the smallest of them. Many people who

live in the surrounding area around the pit might never be aware

that it is there, despite the fact that the pit and its history

are of great interest and importance to industrial history and

sociology.

|

|

|

Location

The colliery is situated on the road leading up to Wheatley

Hill just south of Clayton West and a little east of Skelmanthorpe.

Although geographically in West Yorkshire it is generally

thought of as a Barnsley pit.

History

Established in 1908 the pit will be the oldest survivor

once PontyPrince goes . Following the closure of others

in the area like Denby Grange and Caphouse Hay Royds will

be the last.

|

(Although caphouse remains as amining museum ) The pit escaped

nationalisation probably because of its size and was operated

by the Flack family as a private concern. This meant working under

licence, not employing more than 50 men and not mining more than

100,000 tonnes per year. In a sense it is considered fortunate

that the mine remained private, or else probably it would have

been closed long ago by the NCB .Its survival ensures the continuation

of employment but also mining as tradition in this area.

|

|

The pit has worked a number of seams including the Beeston

and the Whynn Moor. The whole underground complex is accessed

by twin drifts only, so has no winding gear. The drifts

run under the road and then under Wheatley Hill farm. The

access drifts give way to a four way junction which in turn

lead on to the current workings in the Whynn Moor seam.

Twenty two miners work here, using drill and blast methods

to extract pillar and stall workings. The coal is undercut

prior to boring and blasting. Basic underground loaders

are then used to load coal into half tonne tubs, which are

then wound to the surface by a rope haulage system. The

average seam height of 1.2 meters in the Whynn Moor seam.

|

|

|

|

The mining technology employed here is similar

to that of the Northumberland Blenkinsopp and Welsh Betws mines.

A small but steady production rate of 36,000 tonnes is maintained

at Hay Royds. At these rates of production coal is sold solely

to the domestic market. The mine has full ventilation, consisting

of a main fan in the drift tunnels, drawing fresh air down a ventilation

shaft and several smaller fans at various points in the infrastructure.

It is a feature which was often ignored in the smaller mines.

|

|

|

Reserves.

As the Whynn Moor seam is not currently worked at any remaining

mine, and has never been worked at Caphouse or Denby Grange

the mine would seem to have exclusive rights to this seam.

Research has identified about 300,000 tonnes of reserves,

albeit in small pockets underneath Denby dale. This area

was once within the Denby Grange take. Accessing these reserves

could provide working for nine years, depending on the economic

viability of such a venture. It is not known how much coal

is in the present seam being worked, or in other areas of

the mine. |

Future

As the mines market is entirely for domestic use there is

hope that this area of sale is the least likely to further decline,

although as with all coal markets the threat of heavily subsidised

imports is worrying.

|

| A further sign that the mine does indeed have a viable long

term future is that as of April 2000 the mine has received

governments grants of £86,000, £164,000 and £200,000

;such grants were established for UK pits with healthy long

term prospects, to help through short terms market problems.

David Flack the managing director of the mine, quoted in The

Yorkshire Post said that such grants would be used for "improving

technology" to help secure the long term future of the

pit. |

|

|

|

|

The biggest dark cloud on the horizon is the subject of

insurance. At Betws mine insurance increased from £150,000

to £500,000 a year after a small underground fire.

This led to many weeks of lost production and a similar

small drift in North Derbyshire closed for good recently

after a similar insurance problem. If Hay Ryods can find

a way through the insurance problems, it should be able

to keep going for at least a further five years.

Many thanks to Alex Potts and Gareth Rimmington for

their help and for providing information and images for

this article.

|

|